What Innovations in Mold Manufacturing Are Transforming Pump Castings?

2026-01-09

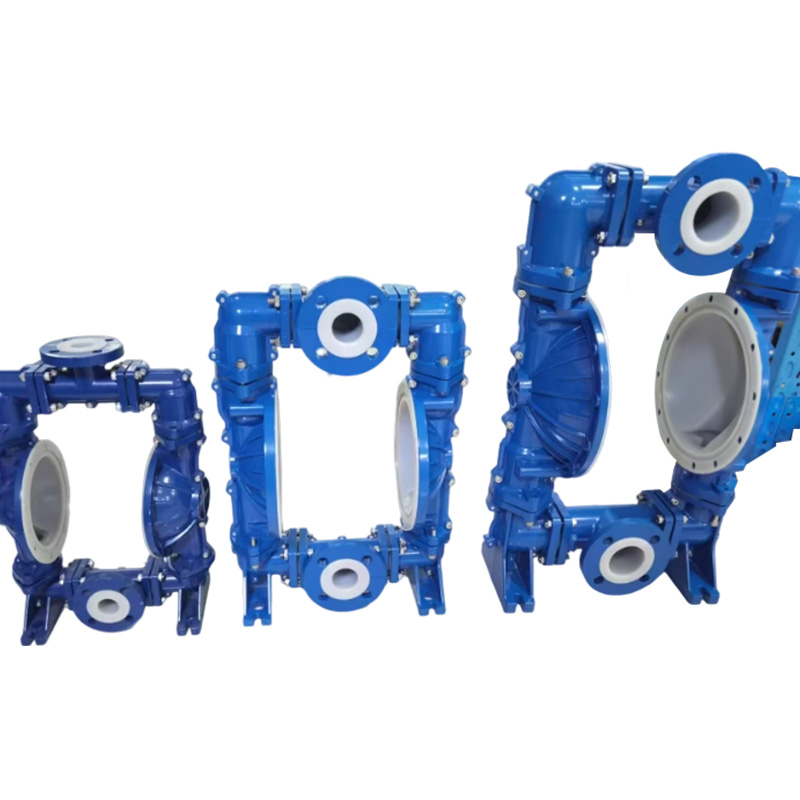

Recent advancements in mold manufacturing are having a profound impact on diaphragm pump castings, improving both their performance and longevity. These innovations address several key challenges in the manufacturing process, such as precision, material compatibility, and cost-effectiveness. As diaphragm pumps are essential in various industries, including agriculture, chemical processing, and water treatment, these improvements in mold manufacturing are making a noticeable difference in the overall functionality and reliability of the pumps.

Enhanced Precision in Mold Design

One of the significant innovations in mold manufacturing is the increased precision achieved through advanced design techniques and technologies. Modern mold manufacturing now incorporates sophisticated computer-aided design (CAD) and computer-aided manufacturing (CAM) systems. These tools allow for the creation of highly detailed and accurate molds that ensure the castings of diaphragm pump components are produced to exact specifications.

This precision is crucial for ensuring the proper fit and alignment of parts such as the diaphragm, valves, and pump housing. When these components are molded with high accuracy, they work more efficiently together, reducing friction and reducing the risk of operational failure. Additionally, more precise molds result in smoother surfaces on the castings, which can contribute to a more uniform flow of fluids through the pump.

Additive Manufacturing and 3D Printing

Additive manufacturing, commonly known as 3D printing, has introduced new possibilities in mold manufacturing. While traditionally used for prototyping, 3D printing is increasingly being used to produce complex mold designs for diaphragm pump castings. The ability to create intricate molds with complex geometries that were previously difficult or costly to achieve is transforming the way pump castings are produced.

3D-printed molds can be customized quickly and cost-effectively, which is particularly beneficial for short production runs or custom pump designs. This flexibility allows manufacturers to experiment with new designs, improving the functionality of diaphragm pumps. For instance, using 3D printing, mold makers can create molds that allow for more precise cooling channels or incorporate features that improve the flow dynamics within the pump.

Furthermore, 3D printing enables faster prototyping and testing, allowing manufacturers to identify potential issues early in the production process. This speed in development reduces the overall time-to-market for new pump designs, which is particularly important in industries that rely on the continuous development of efficient pumping solutions.

Material Advancements for Molds and Castings

The materials used for both the molds and the pump castings themselves have seen significant improvements in recent years. For example, mold manufacturers are now using stronger and more durable materials, such as high-performance steels and specialty alloys, which offer better wear resistance and thermal stability. These materials are crucial when dealing with the high pressures and harsh chemicals that diaphragm pumps often handle.

Moreover, mold makers have also developed new coatings and treatments for molds that help extend their lifespan. These coatings reduce wear and tear during the casting process, which helps maintain mold integrity over multiple production cycles.

Similarly, advancements in casting materials, such as aluminum alloys with improved corrosion resistance and enhanced strength, have a significant impact on the final product. These materials offer better performance in diaphragm pump applications where pumps come into contact with aggressive or abrasive fluids. The innovation in casting materials also contributes to the overall durability and longevity of diaphragm pumps.

Automation and Smart Technologies in Mold Manufacturing

The integration of automation and smart technologies into mold manufacturing has also transformed the process of producing diaphragm pump castings. Automated machines equipped with sensors, robots, and artificial intelligence are now being used to monitor and control various stages of the mold-making process. These technologies ensure that molds are created consistently and accurately, reducing the chances of human error and increasing production efficiency.

For example, smart sensors embedded in the mold-making machines can detect deviations in temperature, pressure, or material composition, allowing for real-time adjustments. This constant monitoring helps maintain consistent quality across all castings, which is particularly important when producing parts that need to meet tight tolerances.

Automation also reduces the time and labor required to produce molds, which can significantly lower manufacturing costs.

English

English русский

русский