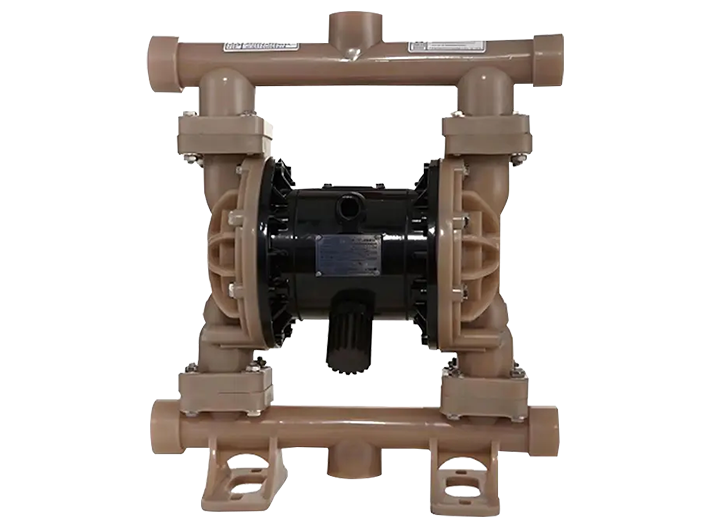

Zhejiang Xiafeng Precision Die Casting Co., Ltd. is a professional China mold manufacturing enterprise specializing in diaphragm pump precision die casting, and integrated R&D and design

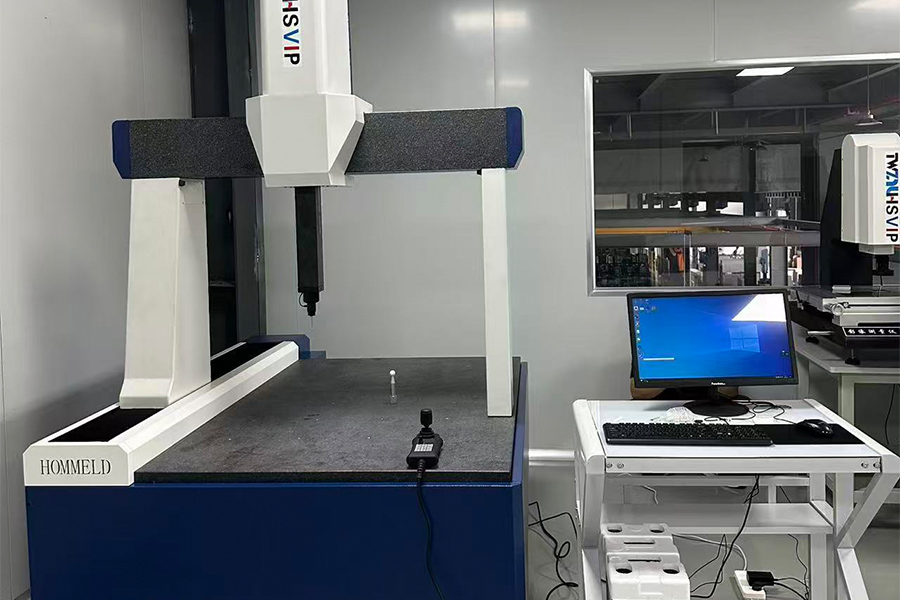

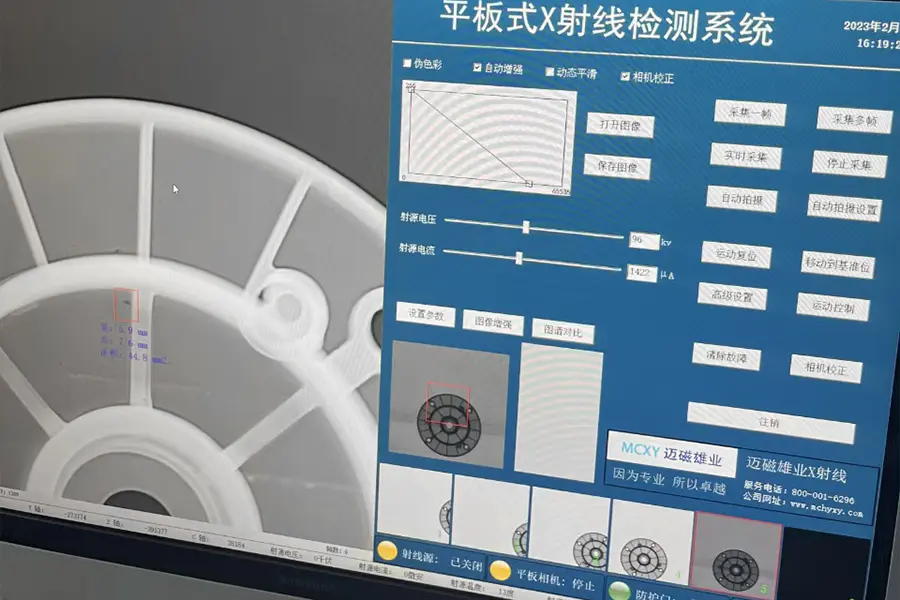

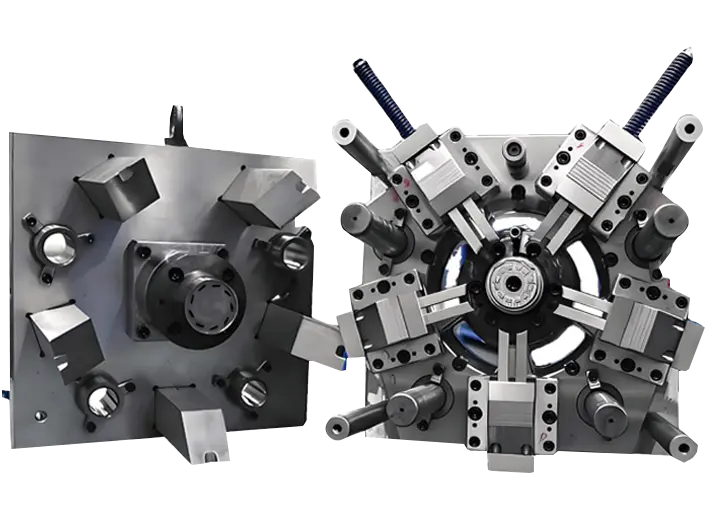

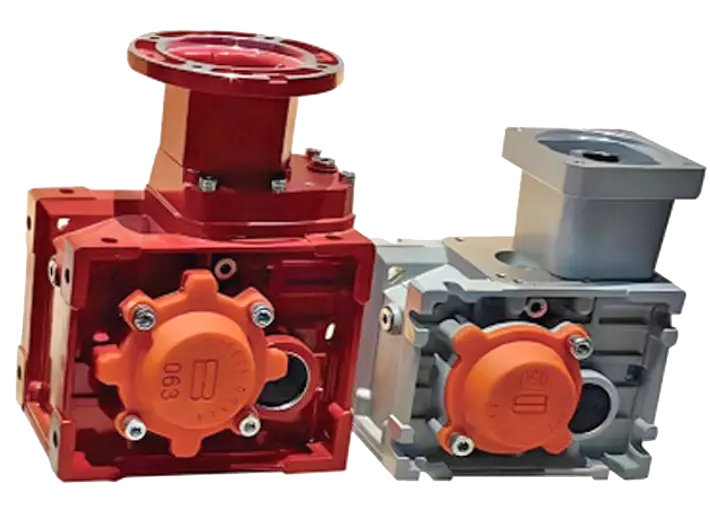

. Our product portfolio includes pneumatic pistons, motor housings, diaphragm pump accessories, reducer components, amusement equipment parts, automotive components, and metal crafts. Located in Wenxi, Qingtian, Lishui, Zhejiang, an area renowned as the "Hometown of Overseas Chinese", the company enjoys a prime geographical location and excellent transport links. Established in 2015, the company occupies an area of over 20,000 square meters and employs more than 50 staff, including over 20 designers and R&D personnel. We offer end-to-end services ranging from mold design and production to product manufacturing, processing, and surface treatment, supported by rigorous quality management and optimized production processes. The facility features a well-planned layout, comprising die casting workshops, precision machining workshops, drilling workshops, shot blasting workshops, pressure testing workshops, grinding workshops, and automated production lines for welding and precision forging. With a monthly production capacity of 500 tons, we manufacture products ranging from 10 grams to 20 kilograms in weight. Equipped with stringent production processes, a variety of intelligent manufacturing equipment, fully equipped standard workshops, and industry-leading testing laboratories, the company ensures the stability and durability of every product. To date, we have obtained over 20 product patents and copyright certificates, along with honors including "Trustworthy Operator," "AAA-Level Enterprise Credit," "Enterprise Recognized for ‘6S’ Management Improvement," "High-Tech Enterprise," "Leading Drafter of Group Standards," "Factory Digital Transformation Application," and "Zhejiang Provincial 'Specialized, Refined, Distinctive, and Innovative' Enterprise."-

CONSULT CUSTOMER SERVICE01

Contact our customer service team to discuss and specify your customization requirements.

-

PROGRAM DESIGN02

Our specialists will formulate and design a solution tailored to your specific needs.

-

-

PRODUCT PROTOTYPING04

Prototypes will be produced according to the approved solution and delivered by the agreed date.

-

CUSTOMER ACCEPTANCE05

Customers will conduct final inspection and acceptance. Comprehensive after-sales service and follow-up support are available at all times.

We provide comprehensive services spanning from mold design and manufacturing to product production, processing, and surface finishing. This integrated approach ensures stringent quality control and optimized production efficiency.

Casting

Machining

One-stop service

More than 10 years of industry experience

-

0+

0+

Covering an area of over 20,000 square meters, it currently has more than 50 employees.

-

0+

0+

The monthly production capacity reaches 500 tons, and the product weight ranges from 10 grams to 20 kilograms.

We have obtained more than 20 product patents and copyright certificates and have a complete quality inspection system.

-

automotive industry

automotive industry

-

Amusement facilities

Amusement facilities

-

Chemical Industry

Chemical Industry

-

coal mines

coal mines

-

medicine

medicine

-

Food industry

Food industry

We will provide high-quality after-sales service, provide you with technical guidance, and guarantee the supply of spare parts.

-

Online Customer Service

Online Customer ServiceOur professional team is online 24/7 to provide you with fast and efficient answers and solutions.

-

One-stop Services

One-stop ServicesWe provide one-stop services, including die-casting, mold manufacturing, machining and more.

-

Warranty

WarrantyFor quality issues or performance failures caused by non-human-induced factors, we provide users with free repair services, replacement of qualified parts, and even return or exchange services when eligible.

-

Quality Assurance

Quality AssuranceThe company has the most stringent production process and various intelligent production and processing equipment to ensure the quality of its products.

-

Leakage is a critical concern in diaphragm pumps, especially when they are handling hazardous or volatile fluids. Diaphragm pump castings, being fundamental components in pump design, are often subjected to high pressures and challenging fluid dynamics. The precision of mold manufacturing plays a pi...

-

Diaphragm pump castings are designed to handle a wide range of demanding applications, including those involving corrosive fluids. The material selection, mold manufacturing techniques, and design considerations all contribute to the pump's ability to effectively manage such fluids. Material Select...

-

Recent advancements in mold manufacturing are having a profound impact on diaphragm pump castings, improving both their performance and longevity. These innovations address several key challenges in the manufacturing process, such as precision, material compatibility, and cost-effectiveness. As diap...

English

English русский

русский