Understanding Diaphragm Pump Castings for Industrial Efficiency

2025-12-17

Industrial fluid handling requires precise equipment to maintain efficiency and safety. Within this context, Diaphragm Pump Factory, High Quality Diaphragm Pump Castings, and Dust Butterfly Valve For Sale play crucial roles in supporting operations across chemical, pharmaceutical, and wastewater industries. Understanding their design, manufacturing, and application can help operators make informed decisions and optimize system performance.

What Makes a Diaphragm Pump Factory Essential for Modern Industry?

A Diaphragm Pump Factory serves as the foundation for producing pumps capable of handling corrosive, viscous, or particulate-laden fluids. Factories specializing in diaphragm pumps focus on stringent quality standards during every stage, from casting to assembly. These facilities often integrate advanced testing equipment to verify flow rates, pressure tolerance, and leak prevention. Industrial buyers need to consider factors such as production capacity, available pump models, and compliance with regional safety regulations when selecting a factory for procurement.

The expertise within these factories influences the reliability and lifespan of the final pump products. For instance, attention to material selection and casting precision reduces failure risks during prolonged operations. A detailed understanding of a factory’s capabilities can assist maintenance engineers and procurement managers in aligning equipment purchases with operational requirements.

How High Quality Diaphragm Pump Castings Affect Performance?

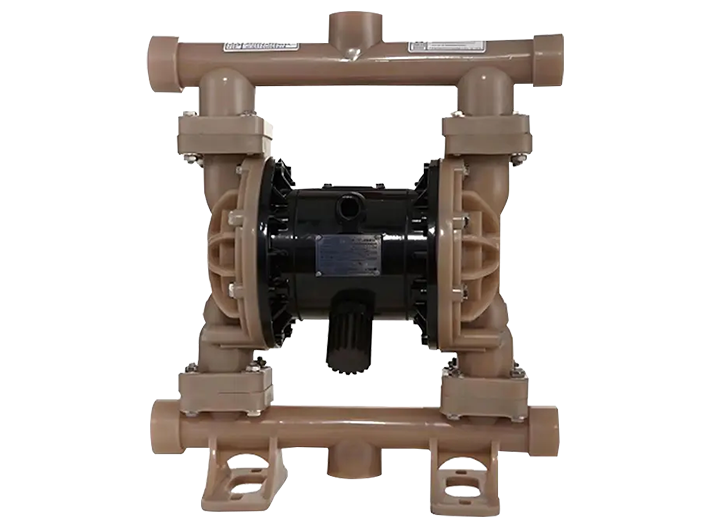

High Quality Diaphragm Pump Castings form the core of pump durability and efficiency. The casting process ensures the structural integrity of pump chambers and fluid paths, which is essential for pumps that handle abrasive or chemically aggressive liquids. Material choices, including stainless steel, aluminum, or specialized alloys, impact corrosion resistance and mechanical strength.

During casting, maintaining uniform wall thickness, proper venting, and heat treatment are critical steps to prevent defects such as porosity or warping. These defects could cause reduced pump efficiency or early mechanical failure. For industries where downtime is costly, selecting castings with documented performance standards helps in reducing maintenance frequency. Furthermore, pumps built with precision castings often demonstrate smoother operation and reduced vibration, which can extend diaphragm life and improve energy consumption over time.

When Should Dust Butterfly Valve Be Used in Industrial Systems?

A Dust Butterfly Valve For Sale is typically integrated into systems where airflow and particulate control are critical. Common applications include pneumatic conveying, dust collection, and material transport systems in cement, coal, or grain industries. The butterfly valve regulates flow by opening or closing the disc within the pipe, enabling precise control over pressure and volume.

Operators need to consider the valve’s material, seal type, and actuator mechanism to ensure compatibility with the operating environment. For instance, high-temperature or abrasive dust conditions demand valves made from durable alloys with reinforced sealing surfaces. Regular inspection of the valve disc, seals, and actuator prevents performance degradation and maintains airflow efficiency. Using a dust butterfly valve appropriately reduces pressure drops, prevents leakage, and protects downstream equipment from wear caused by particulates.

Where Are Diaphragm Pumps Applied Across Industries?

Diaphragm pumps are versatile in applications ranging from chemical transfer and food processing to wastewater management. Their ability to handle slurries, viscous fluids, and abrasive liquids without extensive modifications makes them suitable for complex industrial environments. In food and beverage operations, diaphragm pumps are often constructed with sanitary castings to prevent contamination, while chemical plants prioritize corrosion-resistant materials for handling acids and solvents.

Understanding where and how a diaphragm pump can operate ensures that system designers select models that maintain consistent flow rates and pressure levels while reducing maintenance requirements. Factories producing high-quality pumps typically provide detailed performance curves and installation guidelines, aiding in correct deployment.

Why Choosing the Right Dust Butterfly Valve Matters for Safety?

Incorrect selection or installation of a dust butterfly valve can cause inefficient dust collection, unexpected system pressure drops, or equipment damage. Ensuring that the valve matches the system’s airflow capacity, particulate density, and temperature range is fundamental. Properly selected valves contribute to overall system safety by controlling dust accumulation and preventing potential blockages or overpressure events.

Manufacturers provide specifications including torque requirements, valve size, and seal type, which operators can use to match the valve to system demands. Integrating valves with monitoring systems allows for predictive maintenance, reducing unscheduled downtime.

Who Should Consult With Pump Factories Before Purchase?

Procurement managers, engineers, and maintenance supervisors benefit from early consultation with diaphragm pump factories. Discussing operational requirements, environmental conditions, and expected fluid characteristics ensures that pumps and components are correctly specified. These discussions often cover material options, pump capacities, diaphragm types, and accessory needs. Factories may also provide testing services or custom modifications tailored to industry-specific applications, helping buyers achieve longer service life and stable performance.

How Can Maintenance Improve Diaphragm Pump Lifespan?

Routine maintenance of diaphragm pumps involves inspecting diaphragms, valves, and seals for wear or damage. Cleaning fluid paths, checking torque settings, and verifying pressure ratings are essential practices. Regular maintenance not only extends the life of the pump but also improves operational efficiency and reduces the risk of unplanned shutdowns. Factories supplying high-quality castings often provide maintenance recommendations, including compatible spare parts and replacement schedules.

Custom Applications for Dust Butterfly Valves

Dust butterfly valves are often customized to fit specific operational needs, including varying flange sizes, actuator types, and disc coatings. Customization allows integration into existing systems without modifying upstream or downstream components extensively. In applications where dust particle size varies, selecting a valve with adaptable sealing and actuating mechanisms improves performance and reduces leakage. Custom valves can also include monitoring sensors for real-time feedback on flow and pressure conditions.

Innovations in Pump Casting and Valve Design

Recent developments in casting techniques, such as investment casting and precision sand casting, have improved dimensional accuracy and surface finish of pump components. Advances in coating technology for dust butterfly valves increase resistance to abrasion and temperature fluctuations. These innovations contribute to longer operational life, reduced maintenance intervals, and better system efficiency. Understanding these advancements allows industrial operators to evaluate the trade-offs between cost, performance, and maintenance requirements.

Tips for Evaluating Suppliers of Pumps and Valves

When selecting suppliers, consider certifications, testing capabilities, and historical performance in similar industries. Factory audits, sample testing, and references from previous clients provide insight into production quality and service standards. Documentation on material composition, casting techniques, and valve specifications helps ensure compliance with industry regulations. Transparency in supplier operations allows procurement teams to make informed decisions that align with safety, efficiency, and lifecycle cost goals.

English

English русский

русский