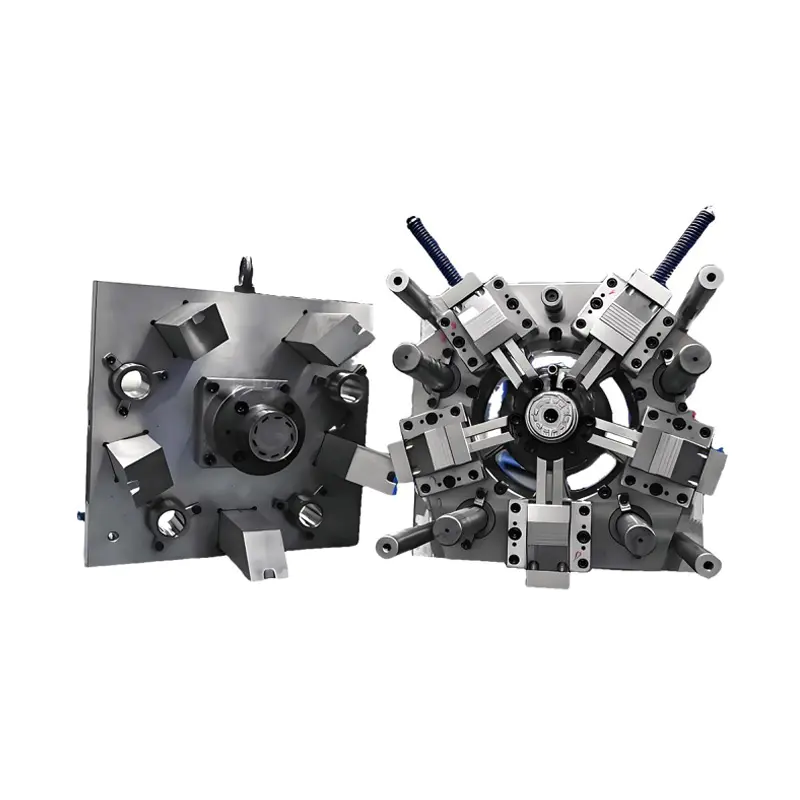

Wholesale Die Casting Molds

Xiafeng provides professional die casting mold design and manufacturing services, combining advanced production technology with years of practical experience. Our die casting molds are engineered for high precision, long service life, and consistent product quality.

Key Features and Capabilities:

Comprehensive Mold Design: Our in-house engineering team designs molds based on customer requirements, material characteristics, and production conditions to ensure dimensional accuracy and stability.

Advanced Equipment: Equipped with high-precision CNC machining centers, EDM, and inspection tools to guarantee tight tolerances and smooth surface finishes.

Material Selection: We use premium mold steels such as H13, 8407, and S136 to ensure strength, wear resistance, and reliable heat treatment performance.

Applications: Die casting molds are widely used in automotive components, lighting housings, electronic enclosures, machinery parts, and communication equipment.

Zhejiang Xiafeng Precision Die Casting Co., Ltd.

Zhejiang Xiafeng Precision Die Casting Co., Ltd. is a professional manufacturing enterprise specializing in precision die casting, mold manufacturing, and integrated R&D and design. Our product portfolio includes pneumatic pistons, motor housings, diaphragm pump accessories, reducer components, amusement equipment parts, automotive components, and metal crafts. Located in Wenxi, Qingtian, Lishui, Zhejiang, an area renowned as the "Hometown of Overseas Chinese", the company enjoys a prime geographical location and excellent transport links.

Established in 2015, the company occupies an area of over 20,000 square meters and employs more than 50 staff, including over 20 designers and R&D personnel. As a China Die Casting Molds suppliers and Wholesale Die Casting Molds factory, we offer end-to-end services ranging from mold design and production to product manufacturing, processing, and surface treatment, supported by rigorous quality management and optimized production processes. The facility features a well-planned layout, comprising die casting workshops, precision machining workshops, drilling workshops, shot blasting workshops, pressure testing workshops, grinding workshops, and automated production lines for welding and precision forging. With a monthly production capacity of 500 tons, we manufacture products ranging from 10 grams to 20 kilograms in weight.

Equipped with stringent production processes, a variety of intelligent manufacturing equipment, fully equipped standard workshops, and industry-leading testing laboratories, the company ensures the stability and durability of every product. To date, we have obtained over 20 product patents and copyright certificates, along with honors including "Trustworthy Operator," "AAA-Level Enterprise Credit," "Enterprise Recognized for ‘6S’ Management Improvement," "High-Tech Enterprise," "Leading Drafter of Group Standards," "Factory Digital Transformation Application," and "Zhejiang Provincial 'Specialized, Refined, Distinctive, and Innovative' Enterprise."

Amidst the industry’s rapid development, Xiafeng remains committed to the craftsman spirit. We have established strong cooperative partnerships with companies such as Kaiqi Group, Yucai Holding Group, Aike Mgke, and Zhejiang Zhanbo Diaphragm Pump, with our sales network covering the entire country. We are dedicated to providing high-quality after-sales services, including technical guidance and guaranteed supply of spare parts for all our clients.

-

Leakage is a critical concern in diaphragm pumps, especially when they are handling hazardous or volatile fluids. Diaphragm pump castings, being fundamental components in pump design, are often subjec...READ MORE

-

Diaphragm pump castings are designed to handle a wide range of demanding applications, including those involving corrosive fluids. The material selection, mold manufacturing techniques, and design con...READ MORE

-

Recent advancements in mold manufacturing are having a profound impact on diaphragm pump castings, improving both their performance and longevity. These innovations address several key challenges in t...READ MORE

-

In the world of diaphragm pump technology, precision mold manufacturing plays a significant role in shaping the overall performance and longevity of diaphragm pumps, particularly those made with alumi...READ MORE

What Defines a Die Casting Mold Structure?

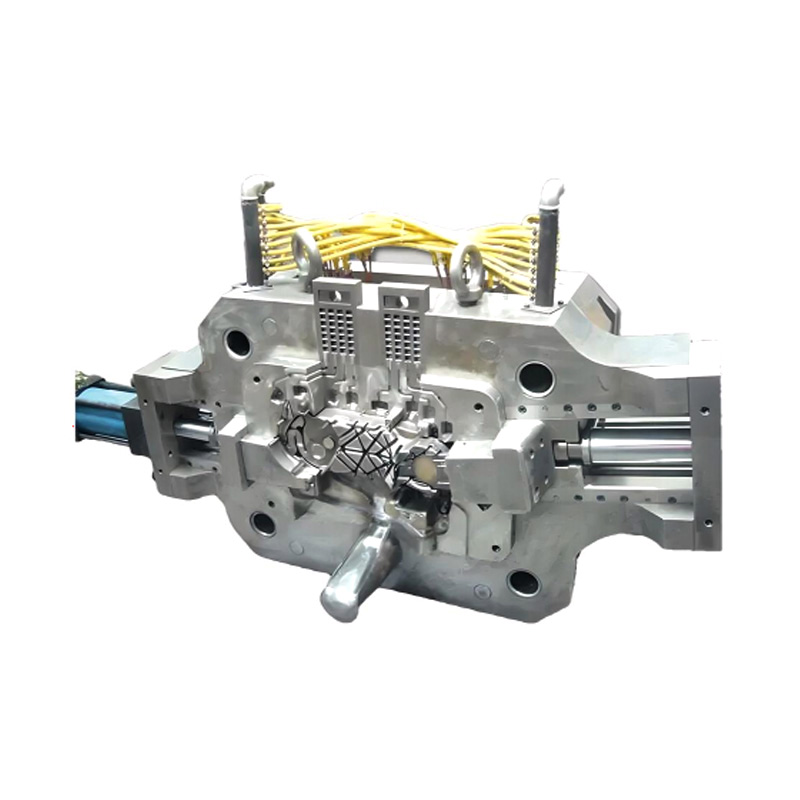

A Die Casting Mold is a precision-engineered tool designed to shape molten metal into a defined geometry under high pressure. Unlike simple molds, it must withstand repeated thermal cycling, mechanical stress, and contact with molten alloys at elevated temperatures. The mold typically consists of two main halves: the fixed half and the moving half, which together form the cavity that determines the final part shape.

From a practical standpoint, cavity design directly affects casting quality. Wall thickness transitions, fillet radii, and draft angles must be carefully planned to ensure proper metal flow and easy ejection. Poor design may result in cold shuts, trapped air, or uneven solidification. Cooling channel layout is another key factor. Efficient thermal control helps balance cycle time and dimensional consistency, especially in high-volume production.

Mold steel selection is equally important. Tool steels are commonly chosen based on thermal fatigue resistance and machinability. Heat treatment processes such as quenching and tempering further enhance mold performance, making the Die Casting Mold capable of long-term operation without excessive deformation.

How Do Metal Die Casting Molds Differ by Application?

Metal Die Casting Molds are not universal tools; they are tailored to specific alloys, machine types, and production goals. Aluminum molds, for example, must handle higher melting temperatures compared to zinc molds, which places greater demands on thermal management and surface treatment.

Machine compatibility also plays a role. Cold chamber and hot chamber die casting machines require different mold configurations. In cold chamber systems, molten metal is ladled into the chamber, so molds must accommodate higher injection pressures. Hot chamber molds, commonly used for zinc alloys, integrate closely with the injection system, influencing gate design and runner layout.

Surface engineering is another area where Metal Die Casting Molds differ. Coatings such as nitriding or PVD layers are often applied to reduce soldering, reduce erosion, and control heat transfer. These treatments do not eliminate wear, but they help extend usable service life under repetitive cycles.

For users, understanding these distinctions answers a common question: why similar-looking molds behave differently in production. Matching mold design to alloy behavior, machine parameters, and expected output volume is essential for stable casting results.

Which Die Casting Mold Parts Need Regular Attention?

Die Casting Mold Parts are the functional components that enable the mold to operate efficiently over thousands or millions of cycles. These include cores, slides, ejector pins, guide pillars, runner systems, and cooling components. Each part has a specific role, and failure in one area can affect the entire casting process.

Ejector systems are a frequent focus in maintenance planning. Pins must move smoothly to release the casting without causing deformation or surface marks. Wear on ejector pins or sleeves can cause sticking parts or uneven ejection forces. Regular inspection and replacement schedules help prevent unexpected downtime.

Slides and cores enable complex geometries such as undercuts or internal features. These moving parts are subject to friction and thermal expansion, making lubrication and alignment critical. Improper slide movement can result in flash or dimensional deviation.

Cooling components, including baffles and water channels, are often overlooked because they are not visible during operation. Blockages caused by scale or debris reduce cooling efficiency, causing localized overheating and increased thermal stress on the mold.

Across all three aspects, a consistent theme emerges: die casting performance depends on both design decisions and ongoing management. A well-engineered Die Casting Mold provides the foundation, Metal Die Casting Molds adapt that foundation to specific alloys and machines, and properly maintained Die Casting Mold Parts keep the system functioning within controlled parameters. When these elements are understood as a complete system rather than isolated components, manufacturers can make more informed choices about tooling investment, production planning, and long-term process stability.

English

English русский

русский