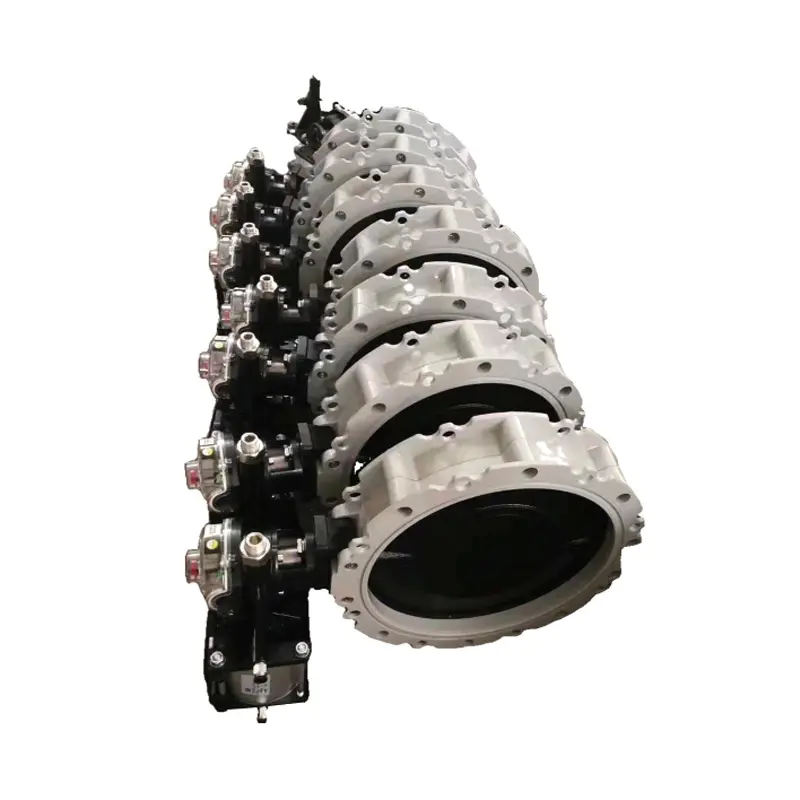

Pneumatic Dust Butterfly Valve and Accessories Supplier

The Pneumatic Dust Butterfly Valve is a flow control and direction-switching device designed for the handling of particulate and powder materials in pipeline systems. It is primarily used for diverting, merging, or isolating material flow, ensuring reliable control under high dust conditions.

Structural Design:

This valve features a top-mounted structure that minimizes the number of body connection bolts, enhancing mechanical stability and operational reliability.

Material and Sealing Options:

The valve body is made of high-strength aluminum alloy for lightweight durability, while the rotating disc is constructed from polymer material to ensure low friction and high wear resistance. Available sealing types include both soft and hard sealing configurations to meet different process requirements.

Specifications:

Nominal Diameter: DN50–DN300

Nominal Pressure: PN1.0–1.6 MPa

Drive Mode: Pneumatic actuator (quarter-turn type), supporting on/off and regulating control

Application Fields:

The Pneumatic Dust Butterfly Valve and its accessories are widely applied in coal chemical, mining, powder conveying, and pharmaceutical industries. It is suitable for controlling or shutting off media containing solid particles and for pneumatic conveying systems.

Intelligent Control:

Some models integrate smart control technology with built-in sensors and communication modules supporting industrial protocols. This enables remote monitoring, status feedback, and precise control, improving automation and operational safety.

Zhejiang Xiafeng Precision Die Casting Co., Ltd.

Zhejiang Xiafeng Precision Die Casting Co., Ltd. is a professional manufacturing enterprise specializing in precision die casting, mold manufacturing, and integrated R&D and design. Our product portfolio includes pneumatic pistons, motor housings, diaphragm pump accessories, reducer components, amusement equipment parts, automotive components, and metal crafts. Located in Wenxi, Qingtian, Lishui, Zhejiang, an area renowned as the "Hometown of Overseas Chinese", the company enjoys a prime geographical location and excellent transport links.

Established in 2015, the company occupies an area of over 20,000 square meters and employs more than 50 staff, including over 20 designers and R&D personnel. As a China Pneumatic Dust Butterfly Valve and Accessories suppliers and Wholesale Pneumatic Dust Butterfly Valve and Accessories factory, we offer end-to-end services ranging from mold design and production to product manufacturing, processing, and surface treatment, supported by rigorous quality management and optimized production processes. The facility features a well-planned layout, comprising die casting workshops, precision machining workshops, drilling workshops, shot blasting workshops, pressure testing workshops, grinding workshops, and automated production lines for welding and precision forging. With a monthly production capacity of 500 tons, we manufacture products ranging from 10 grams to 20 kilograms in weight.

Equipped with stringent production processes, a variety of intelligent manufacturing equipment, fully equipped standard workshops, and industry-leading testing laboratories, the company ensures the stability and durability of every product. To date, we have obtained over 20 product patents and copyright certificates, along with honors including "Trustworthy Operator," "AAA-Level Enterprise Credit," "Enterprise Recognized for ‘6S’ Management Improvement," "High-Tech Enterprise," "Leading Drafter of Group Standards," "Factory Digital Transformation Application," and "Zhejiang Provincial 'Specialized, Refined, Distinctive, and Innovative' Enterprise."

Amidst the industry’s rapid development, Xiafeng remains committed to the craftsman spirit. We have established strong cooperative partnerships with companies such as Kaiqi Group, Yucai Holding Group, Aike Mgke, and Zhejiang Zhanbo Diaphragm Pump, with our sales network covering the entire country. We are dedicated to providing high-quality after-sales services, including technical guidance and guaranteed supply of spare parts for all our clients.

-

Leakage is a critical concern in diaphragm pumps, especially when they are handling hazardous or volatile fluids. Diaphragm pump castings, being fundamental components in pump design, are often subjec...READ MORE

-

Diaphragm pump castings are designed to handle a wide range of demanding applications, including those involving corrosive fluids. The material selection, mold manufacturing techniques, and design con...READ MORE

-

Recent advancements in mold manufacturing are having a profound impact on diaphragm pump castings, improving both their performance and longevity. These innovations address several key challenges in t...READ MORE

-

In the world of diaphragm pump technology, precision mold manufacturing plays a significant role in shaping the overall performance and longevity of diaphragm pumps, particularly those made with alumi...READ MORE

What Problems Does a Dust Butterfly Valve Solve?

A Dust Butterfly Valve is mainly used in pipelines or equipment where dry bulk materials such as cement, flour, fly ash, or chemical powders are conveyed. Unlike liquid valves, it must address particle accumulation, abrasion, and sealing challenges caused by fine solids.

Structurally, this type of valve usually features a short face-to-face length and a circular disc that rotates to open or close the passage. The sealing design is particularly important. Soft seals made from elastomers or polymer materials are often used to compensate for uneven particle distribution and to reduce leakage when the valve is closed. However, users should understand that sealing performance depends on particle size, flow velocity, and pressure conditions.

In practical operation, Dust Butterfly Valves are commonly installed at hopper outlets, screw conveyor inlets, or pneumatic conveying lines. One frequent user concern is material build-up around the disc edge. This can increase operating torque over time. Choosing appropriate disc geometry and maintaining regular cleaning schedules helps reduce this issue. The valve is generally intended for on-off control rather than precise flow regulation, which answers a common question about its functional limitations.

How Do Pneumatic Dust Butterfly Valve and Accessories Work Together?

A Pneumatic Dust Butterfly Valve and Accessories system introduces automated control into dust handling processes. Instead of manual operation, a pneumatic actuator uses compressed air to rotate the valve disc, allowing remote or integrated control within a production line.

The actuator is only one part of the system. Accessories such as solenoid valves, air filters, pressure regulators, limit switches, and position indicators play a supporting role. For example, air preparation units ensure that compressed air entering the actuator is clean and dry, reducing wear on seals and internal components. Limit switches provide feedback to control systems, confirming whether the valve is fully open or closed.

From an application standpoint, pneumatic operation is useful in environments where frequent valve cycling is required or where manual access is limited. It also supports integration with PLC-controlled systems, enabling coordinated operation with feeders, conveyors, or dust collectors.

However, users should consider air supply stability. Inconsistent air pressure may result in incomplete valve movement, causing material leakage or flow interruption. Proper sizing of the actuator and matching it with valve torque requirements is essential. Accessories are not optional add-ons but functional elements that influence response time, safety, and long-term performance.

When Is a Gear Operated Butterfly Valve Suitable?

A Gear Operated Butterfly Valve is designed for manual operation with reduced effort, especially in larger valve sizes or higher torque conditions. Instead of a direct handle, a gearbox transmits force through gears, allowing smoother and more controlled disc movement.

This configuration is often used in systems where automation is unnecessary or where simplicity and mechanical control are preferred. In dust handling applications, gear operation provides better control when material resistance increases due to compaction or buildup. The gearbox also helps maintain disc position, preventing unintended movement caused by vibration or pressure fluctuations.

One practical consideration is maintenance. Gearboxes require periodic lubrication and inspection to ensure consistent performance. While they reduce operator effort, they introduce additional mechanical components that must be protected from dust ingress. Sealed housings and appropriate mounting orientation help extend service intervals.

Gear Operated Butterfly Valves are typically chosen for isolation duties in silos, transfer lines, or processing units where valve size and torque exceed comfortable manual limits but do not justify pneumatic systems.

These three valve types illustrate different approaches to controlling dry bulk materials. A Dust Butterfly Valve addresses fundamental flow isolation needs, Pneumatic Dust Butterfly Valve and Accessories support automation and system integration, and a Gear Operated Butterfly Valve balances manual control with mechanical assistance. Evaluating material characteristics, operating frequency, and control expectations allows these solutions to be applied effectively within dust and powder handling systems.

English

English русский

русский