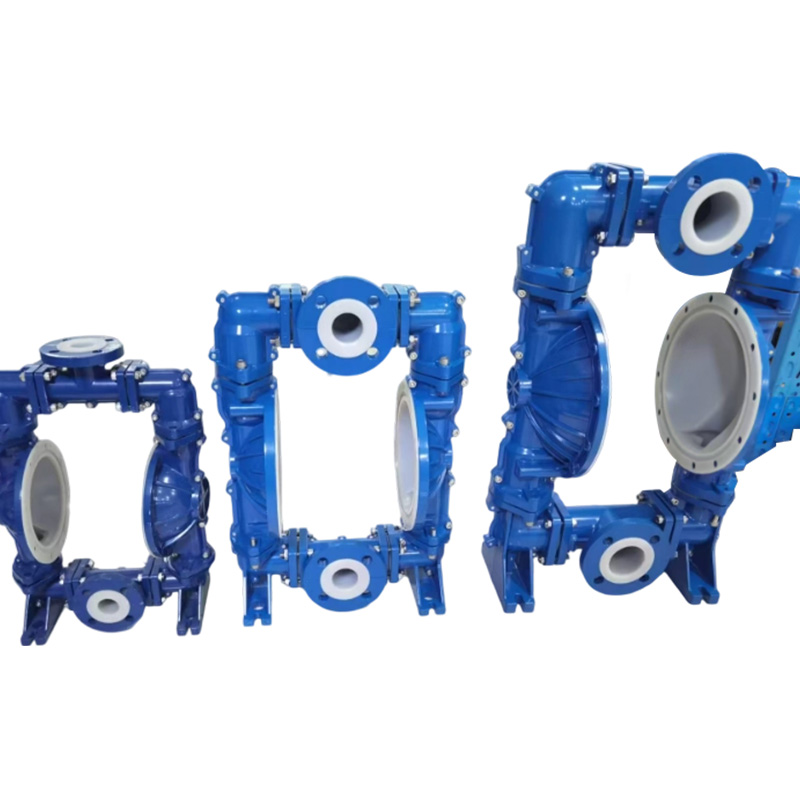

Aluminum Alloy Diaphragm Pumps Factory

Aluminum alloy diaphragm pumps are pneumatic double-diaphragm pumps whose fluid-contacting body is made of lightweight yet strong aluminum alloy. This material provides a high strength-to-weight ratio and excellent corrosion resistance, especially when treated with anodization or epoxy coatings.

These pumps are self-priming (with suction reach up to ~5 m), and flow/pressure can be finely adjusted by modulating the air valve.

Because they lack rotating parts and shaft seals, aluminum diaphragm pumps isolate the pumped medium from mechanical components, minimizing leakage risk and enabling safe handling of toxic, volatile, or corrosive fluids.

Zhejiang Xiafeng Precision Die Casting Co., Ltd.

Zhejiang Xiafeng Precision Die Casting Co., Ltd. is a professional manufacturing enterprise specializing in precision die casting, mold manufacturing, and integrated R&D and design. Our product portfolio includes pneumatic pistons, motor housings, diaphragm pump accessories, reducer components, amusement equipment parts, automotive components, and metal crafts. Located in Wenxi, Qingtian, Lishui, Zhejiang, an area renowned as the "Hometown of Overseas Chinese", the company enjoys a prime geographical location and excellent transport links.

Established in 2015, the company occupies an area of over 20,000 square meters and employs more than 50 staff, including over 20 designers and R&D personnel. As a China Aluminum Alloy Diaphragm Pumps suppliers and Wholesale Aluminum Alloy Diaphragm Pumps factory, we offer end-to-end services ranging from mold design and production to product manufacturing, processing, and surface treatment, supported by rigorous quality management and optimized production processes. The facility features a well-planned layout, comprising die casting workshops, precision machining workshops, drilling workshops, shot blasting workshops, pressure testing workshops, grinding workshops, and automated production lines for welding and precision forging. With a monthly production capacity of 500 tons, we manufacture products ranging from 10 grams to 20 kilograms in weight.

Equipped with stringent production processes, a variety of intelligent manufacturing equipment, fully equipped standard workshops, and industry-leading testing laboratories, the company ensures the stability and durability of every product. To date, we have obtained over 20 product patents and copyright certificates, along with honors including "Trustworthy Operator," "AAA-Level Enterprise Credit," "Enterprise Recognized for ‘6S’ Management Improvement," "High-Tech Enterprise," "Leading Drafter of Group Standards," "Factory Digital Transformation Application," and "Zhejiang Provincial 'Specialized, Refined, Distinctive, and Innovative' Enterprise."

Amidst the industry’s rapid development, Xiafeng remains committed to the craftsman spirit. We have established strong cooperative partnerships with companies such as Kaiqi Group, Yucai Holding Group, Aike Mgke, and Zhejiang Zhanbo Diaphragm Pump, with our sales network covering the entire country. We are dedicated to providing high-quality after-sales services, including technical guidance and guaranteed supply of spare parts for all our clients.

-

Mold manufacturing is a critical process in producing aluminum castings, which are key components in diaphragm pump construction. The precision and quality of the molds directly impact the overall per...READ MORE

-

Leakage is a critical concern in diaphragm pumps, especially when they are handling hazardous or volatile fluids. Diaphragm pump castings, being fundamental components in pump design, are often subjec...READ MORE

-

Diaphragm pump castings are designed to handle a wide range of demanding applications, including those involving corrosive fluids. The material selection, mold manufacturing techniques, and design con...READ MORE

-

Recent advancements in mold manufacturing are having a profound impact on diaphragm pump castings, improving both their performance and longevity. These innovations address several key challenges in t...READ MORE

How Does Aluminum Alloy Diaphragm Pump Casting Matter?

Aluminum Alloy Diaphragm Pump Casting forms the structural base of many diaphragm pumps, including the pump body, fluid chambers, and connection interfaces. Aluminum alloys are selected primarily for their balance between mechanical strength and reduced weight, which becomes especially relevant when pumps need to be moved frequently or installed on mobile systems.

From a manufacturing perspective, casting quality has a direct impact on pump performance. Uniform wall thickness supports consistent stress distribution during pressure cycles, while well-designed internal contours help guide fluid flow smoothly. Poor casting design may create dead zones where media accumulates, increasing cleaning difficulty or accelerating wear on diaphragms and check valves.

Another practical concern is corrosion behavior. Aluminum alloys offer resistance to many neutral and mildly corrosive fluids, but they are not suitable for all chemicals. Users should evaluate media composition carefully, particularly when handling strong acids or alkaline solutions. Surface treatments such as anodizing or coating are sometimes applied to enhance resistance and extend service life.

Dimensional accuracy is equally important. Precise castings ensure correct alignment between diaphragms, valve seats, and fasteners, reducing the risk of leakage. For operators, recognizing the role of casting quality helps explain why pumps with similar external sizes may perform differently under identical conditions.

Why Choose Aluminum Alloy Diaphragm Pumps?

Aluminum Alloy Diaphragm Pumps combine lightweight housings with the operational characteristics of diaphragm-based fluid movement. This configuration is often used in industries where portability, moderate chemical compatibility, and mechanical simplicity are required.

One practical advantage is ease of handling. Compared with cast iron or stainless steel alternatives, aluminum alloy housings reduce overall pump weight, making installation and relocation less labor-intensive. This is particularly useful in maintenance operations, temporary fluid transfer tasks, or applications involving frequent repositioning.

From an operational standpoint, these pumps are suitable for transferring liquids with suspended solids, viscous fluids, or shear-sensitive materials.

However, users should consider pressure limitations. Aluminum alloy housings may not be suitable for extremely high-pressure applications compared with heavier materials. Temperature tolerance is another factor; prolonged exposure to high temperatures can affect both the alloy structure and elastomer components. Selecting appropriate diaphragm materials and understanding operating limits helps avoid premature component fatigue.

In daily use, Aluminum Alloy Diaphragm Pumps are commonly found in coating systems, wastewater handling, and light chemical processing, where material compatibility and manageable weight are key considerations.

What Distinguishes a Gas Powered Diaphragm Pump?

A Gas Powered Diaphragm Pump operates using compressed gas, typically air, to drive diaphragm movement instead of an electric motor. This drive method introduces a different set of operational characteristics that are valuable in specific environments.

One major consideration is safety. Gas-powered operation eliminates electrical sparks, making these pumps suitable for hazardous locations where flammable vapors or dust may be present. Flow control is also straightforward; adjusting gas pressure directly affects pump speed and output without the need for complex control systems.

From a functional perspective, these pumps can run intermittently and tolerate dry operation for limited periods without immediate damage. This tolerance is useful in transfer tasks where fluid supply is inconsistent. However, gas quality plays an important role. Moisture, oil, or debris in the gas supply can affect valve response and diaphragm motion, so filtration and regulation are necessary.

Energy efficiency should also be evaluated realistically. While gas powered systems offer flexibility, compressed gas generation can be energy-intensive. Users should consider total system efficiency rather than focusing only on pump performance.

When viewed together, these three topics illustrate how material choice, pump structure, and drive method interact in diaphragm pump applications. Aluminum Alloy Diaphragm Pump Casting determines structural integrity and compatibility, Aluminum Alloy Diaphragm Pumps address mobility and general-purpose transfer needs, and Gas Powered Diaphragm Pump designs offer operational flexibility in demanding environments. By evaluating actual fluids, site conditions, and maintenance expectations, users can align these technologies effectively with their process requirements.

English

English русский

русский