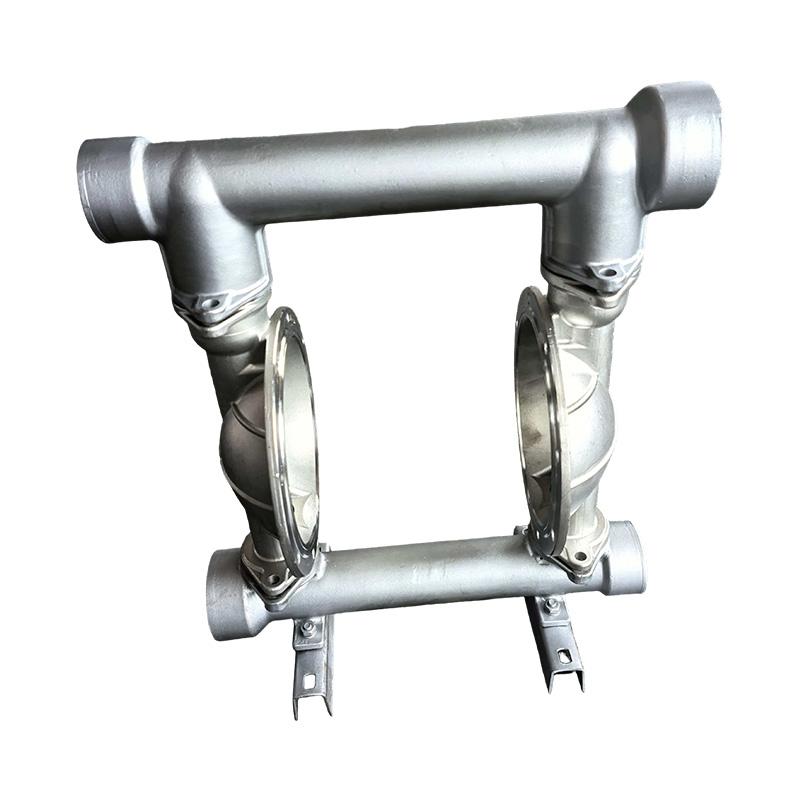

Wholesale Stainless Steel Diaphragm Pumps

Stainless steel diaphragm pumps are built from high-grade stainless steels (e.g., 304 or 316L), giving them superior resistance to acids, alkalis, and solvents. Their polished or electropolished surfaces make them suitable for hygienic applications such as food, beverage, and pharmaceutical industries.

They offer self-priming and dry-running capability, making them adaptable to demanding and intermittent use. With a seal-less design, the risk of leakage is minimized, and modular components like diaphragms and check valves are easy to replace, simplifying maintenance.

Zhejiang Xiafeng Precision Die Casting Co., Ltd.

Zhejiang Xiafeng Precision Die Casting Co., Ltd. is a professional manufacturing enterprise specializing in precision die casting, mold manufacturing, and integrated R&D and design. Our product portfolio includes pneumatic pistons, motor housings, diaphragm pump accessories, reducer components, amusement equipment parts, automotive components, and metal crafts. Located in Wenxi, Qingtian, Lishui, Zhejiang, an area renowned as the "Hometown of Overseas Chinese", the company enjoys a prime geographical location and excellent transport links.

Established in 2015, the company occupies an area of over 20,000 square meters and employs more than 50 staff, including over 20 designers and R&D personnel. As a China Stainless Steel Diaphragm Pumps suppliers and Wholesale Stainless Steel Diaphragm Pumps factory, we offer end-to-end services ranging from mold design and production to product manufacturing, processing, and surface treatment, supported by rigorous quality management and optimized production processes. The facility features a well-planned layout, comprising die casting workshops, precision machining workshops, drilling workshops, shot blasting workshops, pressure testing workshops, grinding workshops, and automated production lines for welding and precision forging. With a monthly production capacity of 500 tons, we manufacture products ranging from 10 grams to 20 kilograms in weight.

Equipped with stringent production processes, a variety of intelligent manufacturing equipment, fully equipped standard workshops, and industry-leading testing laboratories, the company ensures the stability and durability of every product. To date, we have obtained over 20 product patents and copyright certificates, along with honors including "Trustworthy Operator," "AAA-Level Enterprise Credit," "Enterprise Recognized for ‘6S’ Management Improvement," "High-Tech Enterprise," "Leading Drafter of Group Standards," "Factory Digital Transformation Application," and "Zhejiang Provincial 'Specialized, Refined, Distinctive, and Innovative' Enterprise."

Amidst the industry’s rapid development, Xiafeng remains committed to the craftsman spirit. We have established strong cooperative partnerships with companies such as Kaiqi Group, Yucai Holding Group, Aike Mgke, and Zhejiang Zhanbo Diaphragm Pump, with our sales network covering the entire country. We are dedicated to providing high-quality after-sales services, including technical guidance and guaranteed supply of spare parts for all our clients.

-

Leakage is a critical concern in diaphragm pumps, especially when they are handling hazardous or volatile fluids. Diaphragm pump castings, being fundamental components in pump design, are often subjec...READ MORE

-

Diaphragm pump castings are designed to handle a wide range of demanding applications, including those involving corrosive fluids. The material selection, mold manufacturing techniques, and design con...READ MORE

-

Recent advancements in mold manufacturing are having a profound impact on diaphragm pump castings, improving both their performance and longevity. These innovations address several key challenges in t...READ MORE

-

In the world of diaphragm pump technology, precision mold manufacturing plays a significant role in shaping the overall performance and longevity of diaphragm pumps, particularly those made with alumi...READ MORE

Why Choose Stainless Steel Diaphragm Pumps?

Stainless Steel Diaphragm Pumps are primarily selected for applications where hygiene, corrosion resistance, and structural stability are important. Stainless steel housings, commonly manufactured from grades such as 304 or 316, provide resistance to a wide range of chemicals while also supporting cleaning procedures required in regulated industries.

From an operational standpoint, these pumps handle liquids that may be viscous, abrasive, or contain suspended solids. The diaphragm isolates the fluid from the drive mechanism, reducing the risk of contamination and mechanical wear. This makes the pump suitable for processes involving chemicals, solvents, food ingredients, or pharmaceutical intermediates.

Users often question whether stainless steel construction automatically implies suitability for all fluids. In practice, material compatibility still depends on the specific alloy and the fluid composition. Chloride-rich environments, for example, may require careful material selection and surface finishing to reduce corrosion risk. Understanding these limitations helps prevent premature component degradation.

How Does a Stainless Steel Air Diaphragm Pump Operate?

A Stainless Steel Air Diaphragm Pump combines stainless steel fluid-contact components with an air-driven actuation system. Compressed air alternately moves the diaphragms, creating suction and discharge without the need for electric motors.

This operating principle is particularly useful in areas where electrical equipment poses safety concerns or where flexible speed control is needed. Flow rate can be adjusted by changing air pressure, allowing the pump to respond to varying process demands. The absence of rotating seals also reduces leakage points, which is important when handling volatile or sensitive fluids.

However, air quality plays a significant role in long-term performance. Moisture or oil in the compressed air supply can affect air valve operation, causing irregular cycling. Installing appropriate air preparation units supports stable operation. Users should also account for system-level energy considerations, as compressed air generation involves indirect power consumption.

Stainless Steel Air Diaphragm Pump configurations are commonly used in chemical transfer, tank unloading, and clean-in-place systems, where both material compatibility and operational safety are required.

What Defines Heavy-duty Diaphragm Pumps?

Heavy-duty Diaphragm Pumps are designed to withstand higher mechanical loads, extended operating cycles, and demanding process conditions. While they may be constructed from stainless steel or other materials, the defining feature is reinforced design rather than material choice alone.

These pumps often incorporate thicker housings, reinforced diaphragms, and robust valve assemblies. Such design choices allow them to handle higher pressures, abrasive slurries, or continuous operation without frequent maintenance interruptions. In practical terms, this makes them suitable for mining, construction, and large-scale industrial processing.

A common user concern is distinguishing between standard and heavy-duty models. The difference usually lies in duty cycle ratings, allowable pressure ranges, and component service life. Heavy-duty configurations may require more substantial installation support due to increased weight, and maintenance planning should account for the operating environment and media characteristics.

Looking at these three categories together highlights how diaphragm pump technology adapts to different industrial needs. Stainless Steel Diaphragm Pumps emphasize material compatibility and cleanliness, Stainless Steel Air Diaphragm Pump designs add operational flexibility through air-driven control, and Heavy-duty Diaphragm Pumps focus on structural reinforcement for challenging workloads. Taken as a whole, understanding these distinctions allows users to align pump selection with actual process demands, supporting stable operation and manageable maintenance over time.

English

English русский

русский